Checking out the Adaptability and Longevity of Cutting-edge Copper Products in Modern Style

Checking out the Adaptability and Longevity of Cutting-edge Copper Products in Modern Style

Blog Article

The Importance of Quality in the Production of Copper Products

The relevance of quality in the manufacturing of copper items extends far past plain conformity; it is essential to enhancing performance across numerous sectors. Premium copper not only boosts conductivity however also assures sturdiness and integrity, which are essential in applications ranging from electronic devices to vehicle systems. The implications of bad manufacturing techniques can reverberate via expenses and safety standards, inevitably influencing customer count on. As we check out the diverse nature of high quality, the concern emerges: how can producers stabilize these challenges to achieve excellence?

Effect on Product Performance

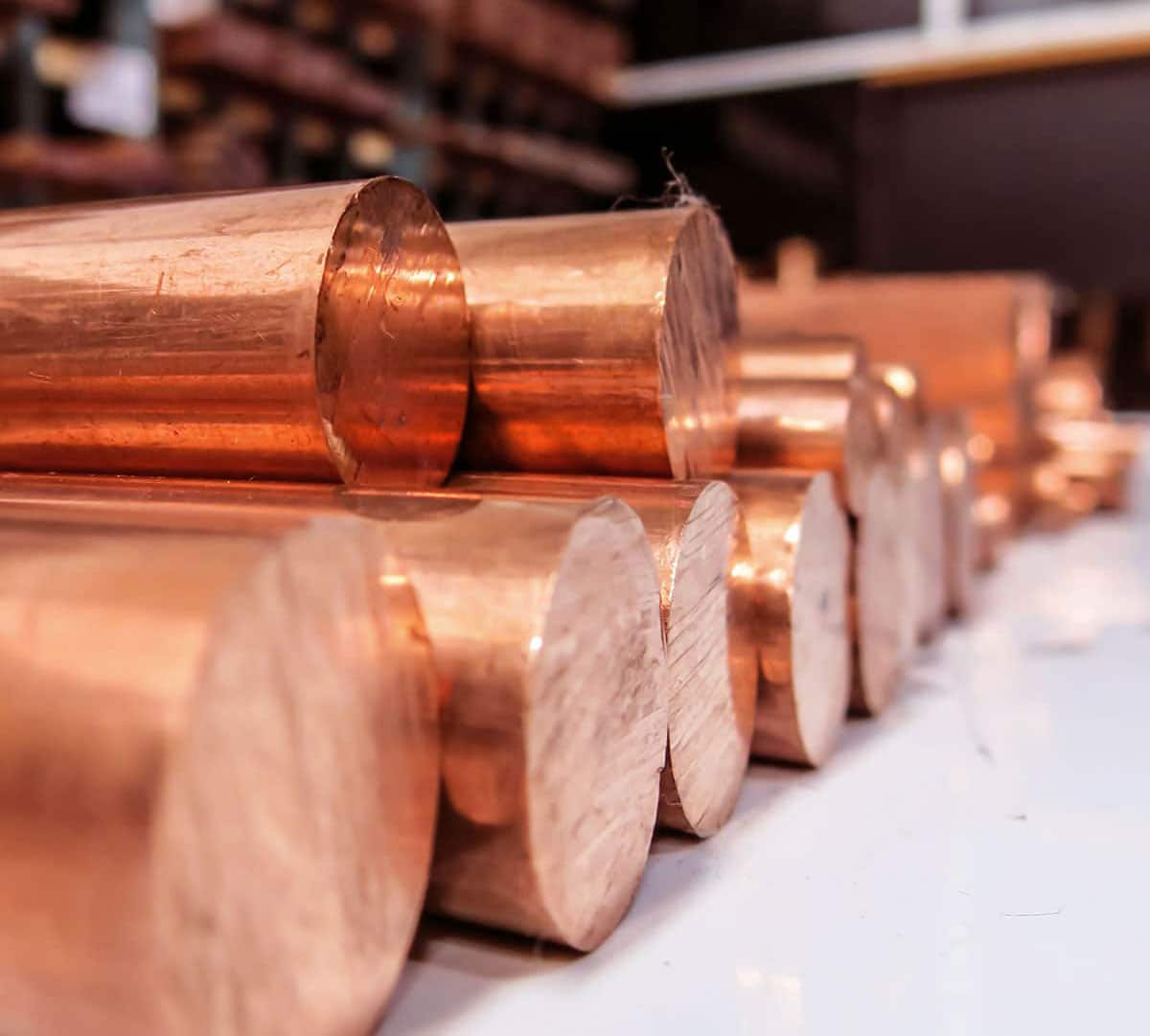

The top quality of copper items plays an essential role in establishing their total performance in different applications. Top notch copper shows remarkable electric conductivity, thermal conductivity, and deterioration resistance, which are important features for sectors such as electronic devices, construction, and auto.

In addition, the mechanical buildings of copper, consisting of ductility and tensile strength, greatly influence its performance in producing processes. Copper products that meet stringent top quality standards can stand up to significant stress without warping, therefore improving durability and lowering the likelihood of failure in demanding settings.

Additionally, the surface finish of copper products influences their efficiency. A smooth, well-treated surface can stop oxidation and various other kinds of deterioration, inevitably lengthening the life of the component. In summary, the high quality of copper items directly affects their functionality, reliability, and long life across various fields, making it crucial for makers to stick to strenuous quality control measures throughout the manufacturing procedure.

Cost Ramifications mediocre

Purchasing high-quality copper items is important, as the cost effects mediocre can be substantial for end-users and manufacturers alike. Poor top quality copper can result in enhanced failing rates, resulting in costly repair work and replacements. Manufacturers might encounter significant downtime as malfunctioning items necessitate recalls or revamp, disrupting manufacturing schedules and impacting general performance.

From an end-user point of view, the implications are equally extreme. Poor-quality copper can bring about ineffectiveness and increased operational prices, as equipment may call for even more frequent upkeep. Eventually, the initial savings gotten from picking lower-quality copper products can be eclipsed by these lasting prices, making the pursuit of quality not just an issue of performance, however a vital financial factor to consider in the manufacturing field.

Security and Conformity Requirements

Making sure safety and security and compliance requirements in the production of copper items is crucial to keeping functional honesty and securing both customers and workers. The manufacturing process must follow rigorous policies stated by companies such as the Occupational Security and Health Management (OSHA) and the Epa (EPA) These guidelines lay out important safety and security techniques, including appropriate handling of basic materials and waste administration, making certain a secure work setting.

Additionally, conformity with sector criteria such as ASTM International and ISO certification is vital. These organizations offer guidelines that assist makers execute best techniques in quality assurance and safety and security steps. Normal audits and assessments ought to be performed to ensure adherence to these standards, as non-compliance can lead to harmful conditions and prospective legal implications.

Customer Depend On and Contentment

Trust fund and contentment among customers play an essential function in the success of copper product manufacturers (Copper Products). Premium copper products not only satisfy rigorous market standards but additionally meet client assumptions, cultivating loyalty and repeat company. When clients are positive in the top quality of the products they acquire, they are more probable to develop a long-lasting relationship with the producer, which can cause references and additional hints positive word-of-mouth

To build this trust fund, producers need to prioritize quality assurance throughout the manufacturing procedure, guaranteeing that each copper product satisfies or exceeds requirements. Transparency in making techniques, paired with dedication to customer support, enhances the assumption of integrity. Timely delivery and responsiveness to client queries considerably enhance contentment degrees.

Customer feedback ought to be actively looked for and integrated right into item advancement cycles to continuously improve offerings. Engaging consumers in dialogue regarding their requirements and choices cultivates a feeling of collaboration, further solidifying their trust in the maker. Eventually, a reputation for quality and customer-centric practices differentiates successful copper product suppliers in an open market, preparing for sustaining customer partnerships.

Lasting Service Success

A producer's dedication to high quality is indispensable to accomplishing long-term company success in the affordable copper products market. High-grade items foster customer loyalty, making sure repeat service and positive references that drive growth. In a market where reliability and efficiency are vital, firms that prioritize high quality over cost-cutting steps are more probable to stand apart.

Additionally, consistent high quality decreases the incident of issues and rework, useful link leading to reduced functional prices and boosted effectiveness. This structured manufacturing procedure allows producers to allocate resources effectively, enabling financial investments in advancement and technology. Services that adjust to spend and market modifications in top quality renovations are much better positioned to meet advancing client needs.

Furthermore, maintaining rigorous top quality standards enhances a company's reputation, bring in brand-new clients and potential partnerships. A robust credibility for high quality can act as a differentiator in congested markets, opening up doors to rewarding agreements and collaborations.

Inevitably, a steadfast dedication to quality not just ensures compliance with market guidelines but also cultivates a sustainable company model. By installing quality right into every facet of the manufacturing process, business can safeguard their place as leaders in the copper items sector, leading the way for withstanding success.

Verdict

In verdict, the importance of top quality in copper item manufacturing is extremely important. As sectors significantly count on copper for crucial applications, keeping rigorous quality control is important to safeguard an affordable benefit and maintain a reliable market visibility.

The importance of top quality in the manufacturing of copper products extends much past plain compliance; it is essential to enhancing performance throughout different markets. In summary, the high quality of copper items directly influences their functionality, integrity, and durability across numerous markets, making it important for makers to adhere to extensive high quality control procedures throughout the production process.

A manufacturer's dedication to quality is integral to achieving dig this long-lasting company success in the competitive copper products market.

Report this page